Amazon SCM: How Is the Supply Chain Arranged?

As the world’s biggest retailer, Amazon needs a massive and sophisticated supply chain to ensure their millions of customers get their orders on time. And that’s exactly what they’ve developed over the last 20 odd years.

So, how does Amazon manage to fulfil all those orders? And what should you do as a seller to ensure your own customers receive their products when they’re supposed to?

Table of contents

Keep reading to learn everything you need to know about the Amazon supply chain and the best strategies for sellers.

How Does the Amazon Supply Chain Work?

As you’ve probably guessed, Amazon’s supply chain operations are extremely complicated. However, we’ve broken down the primary steps that take place after an order is made.

For this example, we’re assuming the item being purchased is sold by Amazon themselves. We’ll outline the options for third-party sellers in the next section.

Here’s how it works:

Customer buys a product.

A robot picks the product from the shelf and delivers it to the sortation system.

The sortation system places the product in a chute. When the product is ready to be packed it’s picked up by an Amazon associate.

The product is packed and then placed on a conveyor belt.

The package is labeled and sent to a delivery truck.

The last step is delivery. This could be by ground if the customer is close by, by air if they live further away, or by Amazon delivery partners via the Flex program.

At this point in their history, the company has developed a well-oiled system that works extremely well. But they’re always striving for improvement. We’ll likely see even more automation and digital technologies introduced in the near future to increase speed, so this process might change in the coming years.

What Shipping Options Do Third-Party Sellers Have?

If you’ve never sold on Amazon before you might be wondering how you’re going to ship your products to customers. The company offers you two programs for fulfilling your orders:

1. Fulfilment by Amazon

After reading about how sophisticated Amazon’s supply chain is, you’re probably wishing you had access to all that fancy technology integration and optimization.

Well actually, you do.

Fulfilment by Amazon (FBA) allows you to ship all of your inventory to Amazon. They’ll store it in one of their warehouses, then pick, pack, and ship your orders as they come in. So, in this scenario, your supply chain will look exactly the same as the one above after someone buys one of your products.

Pros:

You don’t have to store your own inventory. This makes it perfect for individual sellers who don’t have a lot of space. It allows you to buy in bulk without worrying where you’re going to store everything.

It saves you time. You don’t need to pack and ship your orders, leaving you more time to run your business.

Your customers will generally receive their orders faster, since you’re taking advantage of Amazon’s advanced supply chain and logistics system.

If you use FBA your customers will have access to Prime shipping options.

Cons:

You pay more fees. Amazon charges extra for this service, but you can use the Amazon FBA Calculator to find products that have smaller fees to maximize your profits.

You have less control over your packaging. The FBA program has strict rules around packaging that have to be followed, which could limit the ways in which you package your items.

2. Fulfillment by Merchant

The other option is to fulfill your orders yourself. This will give you more control and might lower your costs. But it will also lead to a lot more work.

Pros:

You pay less fees. Because you’re storing and shipping your own inventory you don’t have to pay Amazon to do that for you.

You have better profit margins. With less fees you’ll make more on every sale. This could allow you to charge less for your products, which might lead to more sales.

You have more control over your packaging. You won’t have to follow FBA’s rules and can pack your items however you like.

Cons

You have to store your own inventory. This takes up space, which you might not have. If you have to rent additional space to store products that will eat into your profit margins.

You have to pack and ship your own orders. Depending on how much you’re selling this could be a big time commitment. You either have to take time away from other tasks to complete this, or hire a team to help you, which will increase your costs.

Which Option Should You Choose?

For most individual sellers, FBA will be the best choice. It eliminates many of the barriers to entry that come with starting an e-commerce business and simplifies the entire process. Yes, you’ll have to pay more fees, but for the majority of people it will be worth it.

As one experienced seller puts it:

“Before discovering the power behind FBA I was shipping products out from my garage-orders were going well but FBA takes things to the next level. Your products become ‘Prime’ products and Amazon handles the distribution and customer service for you so massively frees up your time and energy! You can be concentrating on the Marketing of your products-the fun stuff! Thinking of new social media ads, new promotions, new product ideas – honestly, that’s the side I really enjoy!" - Alex Shelton

So, should you ever consider fulfilling orders yourself? Under certain circumstances, sure. This might be a smart choice if you’re a larger business that already has a supply chain in place. You should also consider it if you only plan on selling a few items a month. FBA isn’t really worth it for one or two sales a month.

But for everyone else, FBA is likely the way to go. With this system, all you need to do is to find the right product. And with tools like the AMZScout Pro Extension even that step is super easy now.

The History of Amazon’s Supply Chain

Since its inception, Amazon has been working to improve their supply chain management (SCM). The company clearly realizes that getting people their orders as quickly and seamlessly as possible has a big impact on customer satisfaction.

Here’s a quick timeline that covers some of the major innovations in Amazon’s supply chain:

2005: Amazon Prime is launched, giving members free two-day shipping within the US for eligible products.

2009: Same day shipping is announced and becomes available for select products.

2013: Amazon initiates Operation Dragon Boat, with the goal of eventually owning their entire supply chain.

2013: Amazon starts testing drones as a means of delivering packages.

2014: Amazon purchases a 25% stake in delivery companies Yodel and Colis Privé.

2014: Prime Now launches, offering customers one-hour delivery in select locations.

2015: Amazon Flex launches, allowing independent drivers to sign up and deliver packages.

2016: Amazon Purchases Colis Privé, furthering their strategy of having more control over their supply chain.

2016: Amazon leases 20 aircraft from Air Transportation Services Group.

2018: The company launches Amazon Logistics, it’s own shipping and delivery service that utilizes third-party providers.

2020: Amazon Prime Air, the company’s drone delivery service, receives FAA approval.

It’s clear that gaining more control of their supply chain has been a major focus of Amazon, and for good reason. One of their biggest challenges is ensuring customers receive their orders on time. The more control they have, the more they’ll be able to reduce potential problems during the delivery process.

With the purchase of Colis Privé, and the launch of Amazon Flex and Amazon Logistics, you might argue that the company is just as much a shipping business as a retail business.

Why Amazon SCM is So Effective

It isn’t just the points above that make Amazon’s supply chain so effective. Here are a few other strategies they use to ensure everything goes smoothly once someone places an order:

Cooperation with Third-Party Sellers: The company understands that third-party and individual sellers are a big part of their business. If these sellers don’t have the tools they need then the system isn’t going to work. That’s why Amazon provides sellers with everything they need to fulfil their orders. They also give them access to Fulfillment by Amazon to make things even easier.

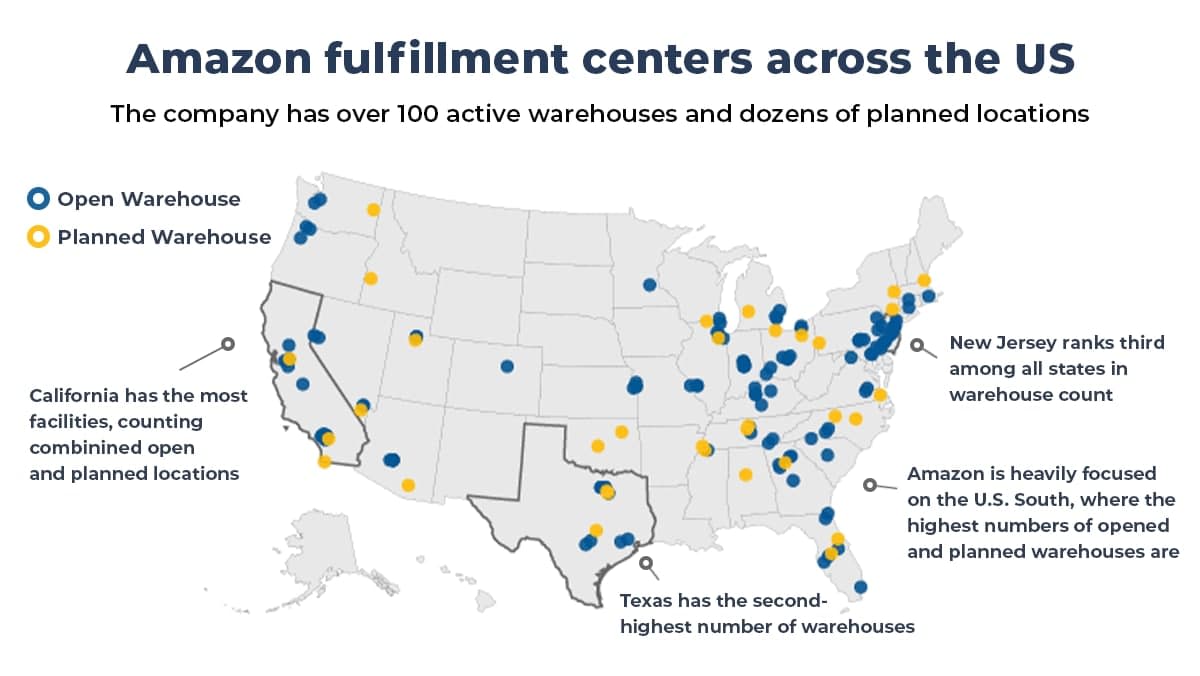

Strategically Placing Warehouses: Amazon won’t just place a warehouse anywhere. They’ve purposefully placed them close to city centers where most of their demand comes from. And now that they have the majority of metropolitan areas covered they plan to place more warehouses in suburban areas to provide better service to even more customers.

A Vast Network of Warehouses: Even more important than where their warehouses are located is how many they have. Amazon currently has over 175 fulfillment centers located all around the world, and they’re planning on continuing to grow that number. More warehouses mean they’ll be able to provide one-day and one-hour shipping to more people.

Automation: Amazon has been a leader in business automation. They’ve continually rolled out new systems and machines that will reduce labor costs and limit mistakes. In recent years, they’ve introduced robots that pick items from storage, scan products, and pack orders, making their warehouses even more efficient.

Offering Multiple Shipping Options: Customers love having more choices. Amazon now offers multiple shipping options, including standard, same-day, and Prime Now. People can decide how fast they want to receive orders and can pay extra for faster shipping if they wish.

Global Supply Chain Management: Amazon sells on 11 marketplaces all around the world, and each marketplace has strategically placed fulfilment centers nearby. This ensures that no matter where customers are ordering from they’ll be able to receive they’re goods in a reasonable amount of time.

The company continues to innovate and find new supply chain solutions, so you can expect further structures to be put in place to help their system function even more efficiently moving forward.

Facts about the Amazon Supply Chain

Want to learn more about Amazon’s supply chain? Here are a few more interesting facts:

1. Most Sellers Use FBA

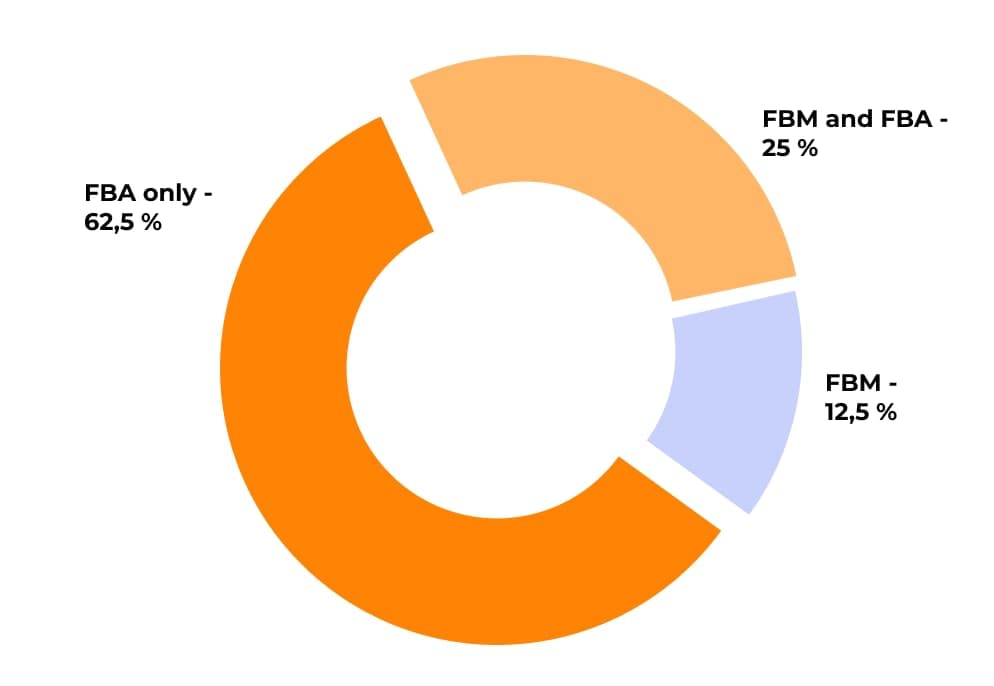

As part of a case study we performed on fulfillment, we surveyed some of our partners on their preferred method. Here’s how the usage breaks down:

FBA only: 62.5 %

Both FBM and FBA: 25 %

FBM Only: 12.5 %

Given the many advantages that FBA provides, it makes sense that the majority of sellers use this system. Even most of the people who use FBM still use FBA for some of their items.

2. Most of Amazon’s Fulfillment Centers are in the US

While the company has warehouses all over the world, over 100 of them are located in the US. That’s well over half of their total locations.

This is because the majority of their business is still in America, which is why most sellers ship their inventory to those warehouses and choose to sell there.

3. The System isn’t Perfect

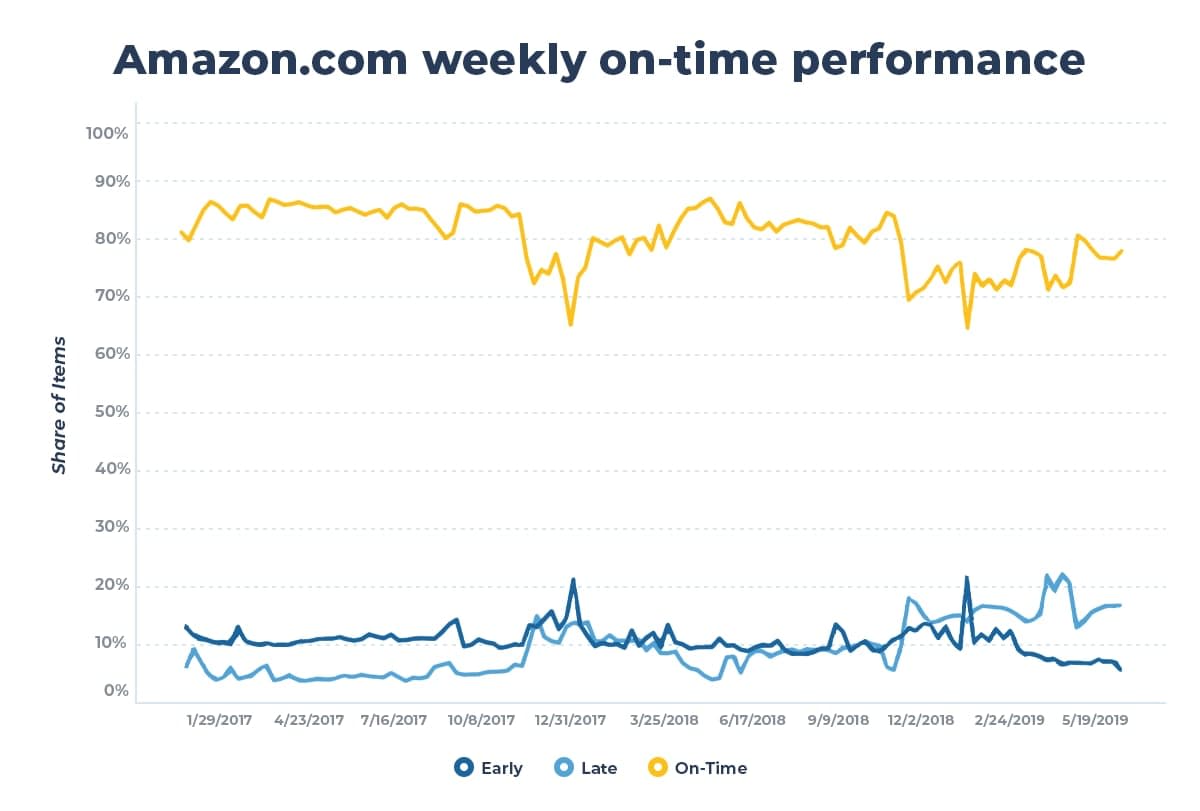

While Amazon has poured a lot of time and resources into developing an exceptional supply chain, it’s far from perfect.

In fact, according to analytics only about 80% of orders arrive on time.

So, even if you opt for the FBA program, be prepared for some of your customers to receive their products late.

4. Amazon Spends More on Logistics Every Year

As we’ve discussed, delivery and logistics is a critical part of Amazon’s business. Because of this, it’s no surprise that as their business grows so do their expenses.

Over the last 10 years, their annual spend on this portion of their business has increased by a staggering 20 times.

Conclusion

Amazon’s business model is one part retail and one part shipping. Because of this, they’ve worked hard to create a supply chain that will meet their growing needs.

But this system doesn’t just benefit consumers. As a seller, you can sign up for the FBA program and use this technology for your own business. Because of this, starting your own e-commerce store has never been easier.